Industry Development Trends

In recent years, the acceleration of infrastructure projects has led to an increasing demand for high-quality aggregates. However, the depletion of natural sand resources and strict mining regulations have made machine-made sand the preferred alternative. At the same time, national environmental policies require mining enterprises to adopt greener, smarter, and more efficient production methods. Modern machine-made sand production lines, characterized by high productivity, low energy consumption, and eco-friendly designs, are widely used in mining, construction, roads, bridges, and other industries.

Key Technological Features of Machine-Made Sand Production Lines

- Intelligent Control Systems: Advanced automation technology enables remote monitoring and data analysis of the production process. Smart sensors and PLC control systems allow real-time adjustments to optimize crushing, screening, and sand-making efficiency, ensuring stable production.

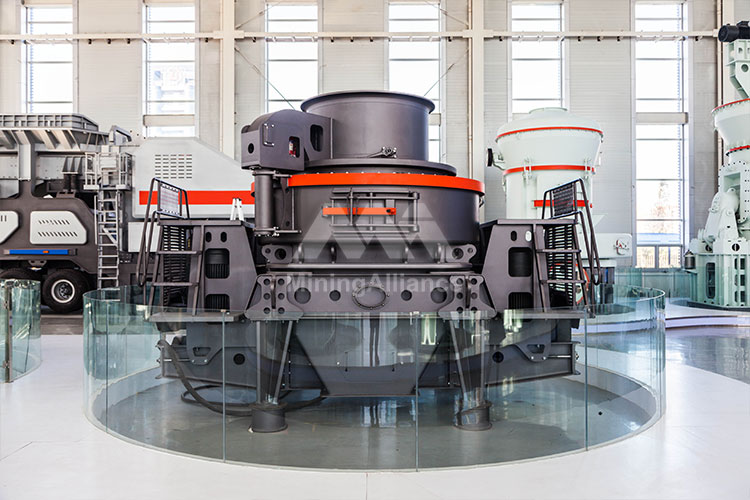

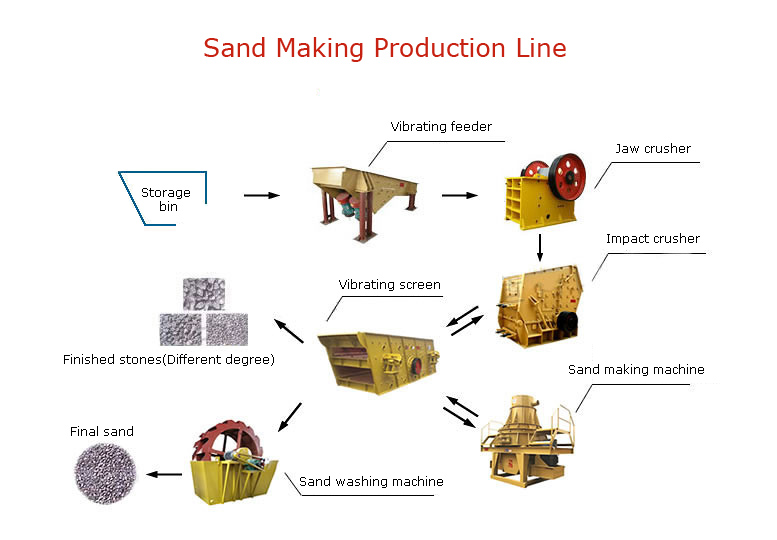

- High-Efficiency Crushing and Sand-Making Technology: A multi-stage crushing process is typically adopted. Jaw crushers perform primary crushing, followed by cone or impact crushers for secondary and tertiary crushing. The core sand-making equipment (such as VSI impact sand-making machines) utilizes high-speed rotating impellers to crush and shape the material, producing well-graded, high-quality sand that meets stringent concrete and construction standards.

- Eco-Friendly Design: High-efficiency pulse dust collectors minimize dust emissions, and enclosed conveyor systems reduce noise pollution. Some production lines also feature wastewater recycling systems, where washing water is treated and reused, conserving resources and reducing environmental impact.

- Wear-Resistant Materials and Long Service Life: Key wear parts of sand-making machines, such as impellers, impact blocks, and protective liners, are made of high-chromium alloy or wear-resistant ceramics. This enhances durability, extends equipment lifespan, and reduces maintenance costs.

Market Advantages of Machine-Made Sand

- Stable Supply: Machine-made sand production lines operate year-round, unaffected by seasonal and environmental factors. This ensures a consistent supply for the construction market, preventing cost increases and project delays caused by natural sand shortages.

- Quality Control: Unlike natural sand, which varies in quality due to geological factors, machine-made sand production can be precisely controlled in terms of particle size, mud content, and gradation. This guarantees compliance with national standards, making it suitable for high-strength concrete and precision construction.

- Wide Application: Machine-made sand is widely used in highways, bridges, railways, airports, and urban infrastructure, with strong market demand and attractive investment returns.

Case Study

A major aggregate company invested in a 5-million-ton-per-year machine-made sand production line in a coastal region. The facility features a fully enclosed workshop and advanced dust and noise suppression systems to ensure compliance with national environmental standards. Additionally, the implementation of an automated control system increased production efficiency by 20% while reducing energy consumption by 15%. The successful operation of this project not only supplied high-quality machine-made sand to the local construction market but also set a benchmark for green mining production, driving the industry toward smarter and more sustainable practices.