Surging Demand for Aggregates Drives Crushing Equipment Upgrades

The continuous expansion of infrastructure projects, highways, railways, and water conservancy projects has led to a growing demand for high-quality aggregates. As a crucial component in secondary and tertiary crushing processes, cone crushers play a vital role in aggregate production. Their superior crushing capacity, precise particle size control, and stable operation make them the preferred choice for many aggregate producers.

Optimized Crushing Chambers Improve Finished Product Quality

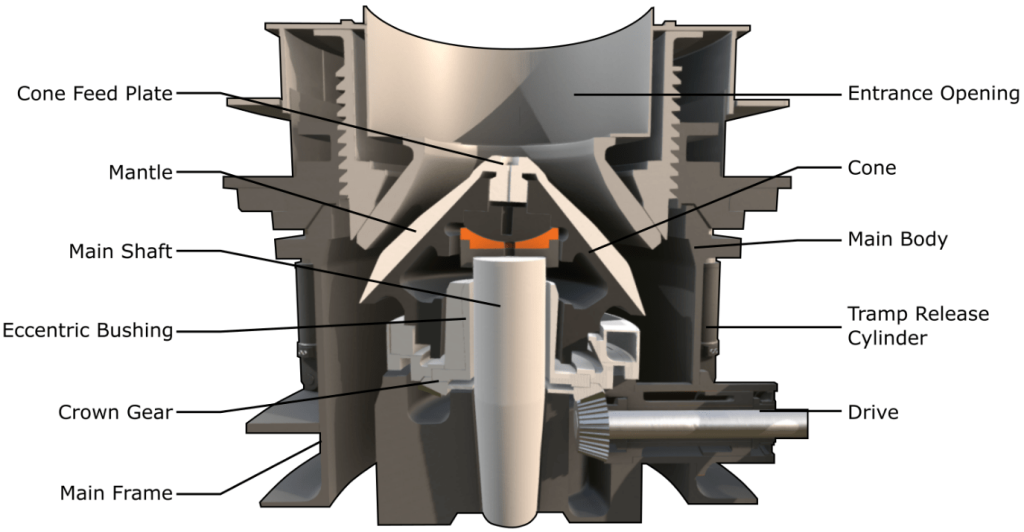

The aggregates industry requires precisely graded and well-shaped materials, which traditional crushers often fail to deliver. Modern cone crushers feature optimized crushing chamber designs tailored for different rock hardness levels, ensuring superior crushing performance. For instance, multi-cylinder hydraulic cone crushers provide better control over particle shape, producing aggregates that meet the stringent requirements of high-grade concrete and asphalt pavements.

Enhanced Adjustability for Diverse Operational Needs

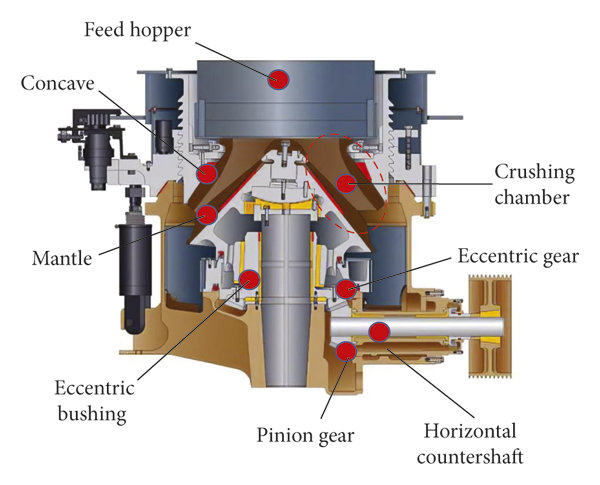

Today's cone crushers offer greater adaptability to different working conditions. Operators can adjust the discharge opening, change the eccentric throw, and optimize liner configurations to meet varying production demands, whether for high-fineness manufactured sand or coarse aggregates. Hydraulic adjustment systems simplify operations, reducing manual intervention and ensuring continuous and stable production.

Intelligent Control Systems Drive Industry Upgrades

The development of digital technology has significantly enhanced the intelligence of crushing equipment. Modern cone crushers are equipped with smart monitoring systems that collect real-time operational data, automatically adjusting crushing parameters through centralized control systems. This not only improves production efficiency but also minimizes downtime and maintenance costs.

Sustainability and Energy Efficiency: The New Industry Standard

With stricter environmental regulations, the aggregates industry is rapidly transitioning toward greener production methods. New-generation cone crushers feature energy-efficient motors and optimized power management systems to reduce overall energy consumption. Moreover, improved chamber designs lower dust emissions during crushing, and many machines now include built-in dust suppression systems to minimize environmental impact. Additionally, advanced noise reduction technologies make these crushers suitable for urban and eco-friendly construction projects.

Smarter, More Automated, and More Efficient

The future of cone crushers lies in increased intelligence, automation, and efficiency. AI-driven algorithms will optimize crushing parameters based on real-time material conditions, ensuring peak performance. Remote maintenance and monitoring technologies will enhance predictive maintenance, reducing human intervention and improving overall productivity. As the demand for high-performance construction materials continues to rise, cone crushers will play an increasingly critical role in supplying top-quality aggregates for infrastructure development.