Advancements in the Mining Industry Drive Crushing Technology Upgrades

With the rapid development of the global mining and infrastructure industries, the demand for efficient and environmentally friendly crushing equipment is increasing. As a core component in mineral processing, cone crushers have recently undergone significant innovations in technology and automation. The latest models offer improved production capacity while optimizing energy consumption, automation, and maintenance convenience, meeting the modern mining industry's demand for high-efficiency and low-energy production.

High-Efficiency Crushing Technology Supports Large-Scale Mineral Processing

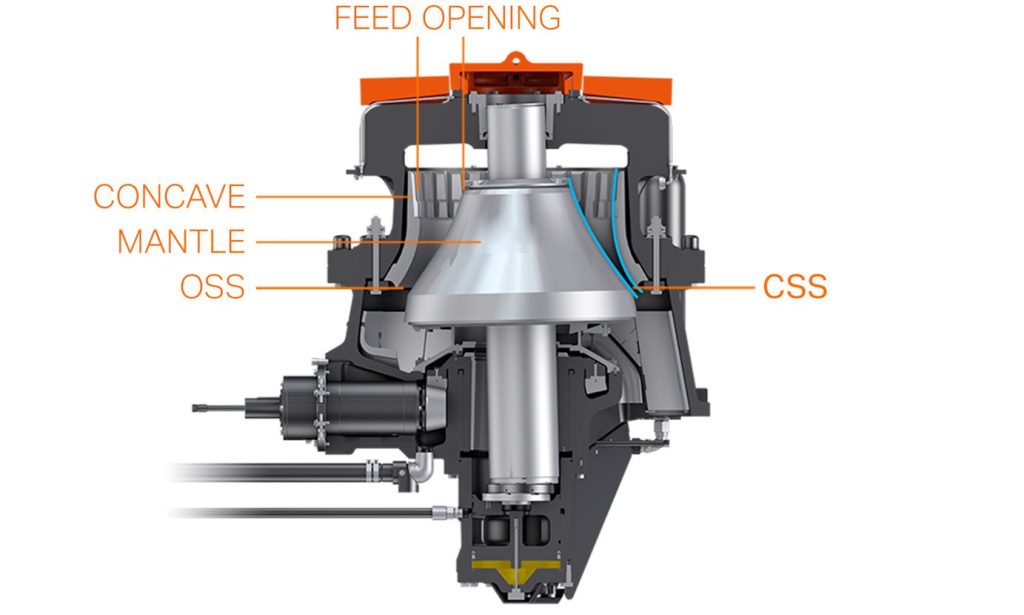

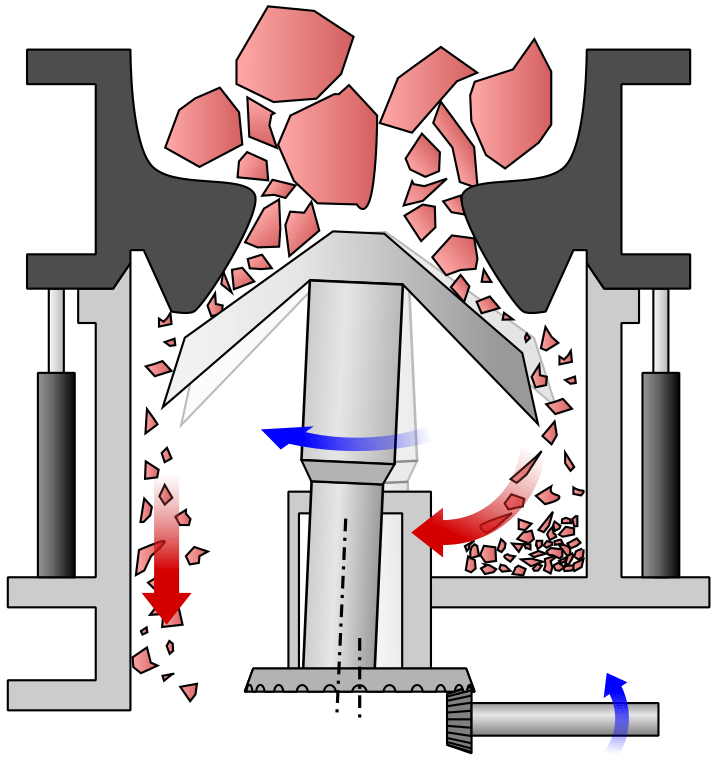

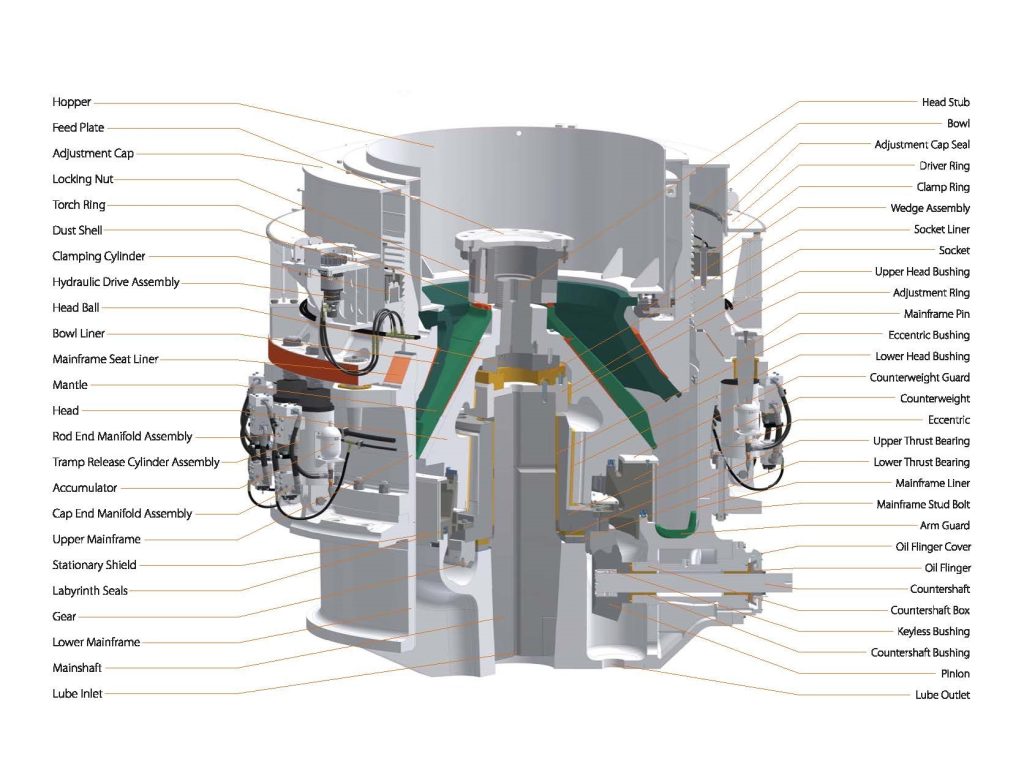

Traditional crushers often struggle with severe wear, high energy consumption, and frequent maintenance when processing hard ores. The latest generation of cone crushers adopts laminated crushing technology, optimizing chamber structure and enhancing crushing force to ensure even pressure distribution on materials. This reduces over-crushing and increases the proportion of high-quality finished products. Additionally, the precise gap control between the moving and fixed cones ensures uniform particle size, making the crusher suitable for various ores, such as iron ore, granite, and basalt.

Intelligent Automation Enhances Equipment Performance

Modern cone crushers are equipped with intelligent control systems that monitor operational status in real time and automatically adjust crushing parameters based on material characteristics to ensure optimal efficiency. Remote monitoring technology allows operators to analyze data and adjust settings as needed, reducing unplanned downtime. Moreover, advanced models feature automatic lubrication systems and hydraulic adjustment mechanisms, further improving stability and longevity.

Eco-Friendly and Energy-Saving Technologies Shape the Future

As the global push for sustainable mining intensifies, the environmental performance of crushing equipment is becoming increasingly important. New cone crushers are designed with high-efficiency motors and optimized transmission systems to reduce energy consumption per ton of material processed. Additionally, advanced dust suppression and noise reduction technologies minimize the environmental impact of crushing operations. Some models also use recyclable wear-resistant materials for key components, promoting sustainability and reducing dependence on natural resources.

The Future of Cone Crushers in Smart Manufacturing

In the future, cone crushers will become even more intelligent and modular. With the integration of artificial intelligence and big data analytics, these machines will achieve self-diagnosis and predictive maintenance, boosting productivity while reducing operational costs. The expansion of 5G and IoT technologies will further enable remote control and fully automated crushing stations, providing safer and more efficient solutions for the mining industry.