Fixed crushing plant and mobile crushing plant each have their advantages and are suitable for different scenarios. Below is an analysis of their key differences and applications:

1. Fixed Crushing Production Line

Characteristics:

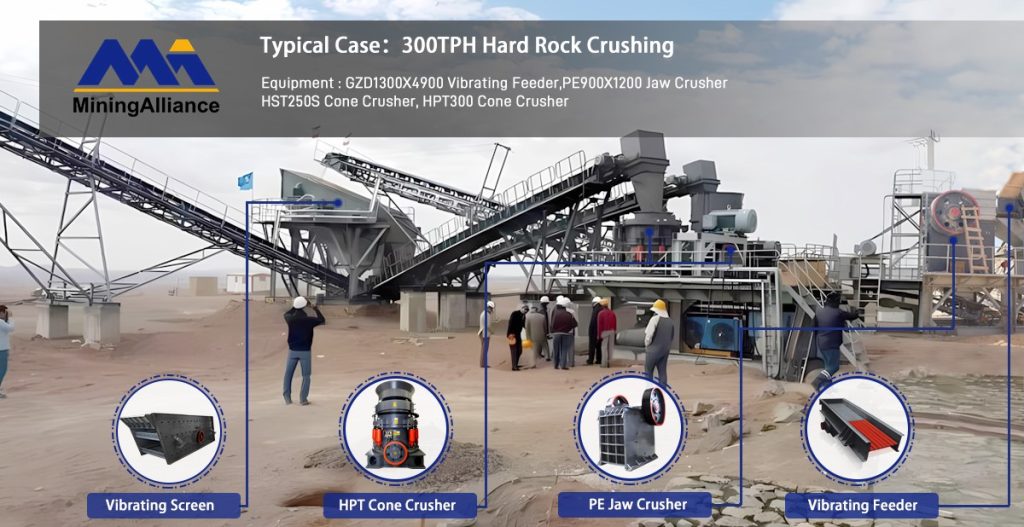

- Stable Structure: Equipment is permanently installed at a specific site, typically including primary crushing (jaw crusher), secondary crushing (impact crusher or cone crusher), and screening equipment.

- High Production Capacity: Generally suitable for large-scale mining, quarries, and construction material production.

- Lower Operating Costs: Stable operation over the long term, with relatively lower maintenance and production costs.

- Higher Initial Investment: Requires a long construction period, foundation work, and fixed installation, leading to higher upfront costs.

Application Scenarios:

- Mining Operations: Suitable for large-scale, long-term mining projects such as iron ore, gold mining, and coal mining.

- Sand and Aggregate Production: Used for producing concrete aggregates, construction sand, etc.

- Large Infrastructure Projects: Ideal for stable material supply in projects like hydropower stations and highway construction.

2. Mobile Crushing Production Line

Characteristics:

- High Flexibility: Equipment can be relocated as needed, making it ideal for temporary projects or scattered raw material locations.

- Quick Deployment: No need for fixed foundations; can be put into operation immediately after transportation to the site.

- Adaptable to Harsh Environments: Suitable for work in mountainous areas, mining regions, and demolition sites.

- Higher Costs: The purchase cost is generally higher than fixed production lines, but it reduces infrastructure costs and is cost-effective for short-term operations.

Application Scenarios:

- Construction Waste Recycling: Ideal for demolition sites where construction waste can be processed and reused.

- Road and Railway Construction: Can be relocated as the project progresses.

- Short-Term Mining Operations: Suitable for seasonal or temporary mining projects without the need for permanent facilities.

3. How to Choose?

| Comparison | Fixed Crushing Production Line | Mobile Crushing Production Line |

| Investment Cost | High upfront investment, lower long-term costs | High equipment cost but lower infrastructure costs |

| Production Capacity | Suitable for large-scale, high-yield production | Lower capacity, suitable for small-scale operations |

| Flexibility | Requires fixed installation, difficult to relocate | Can be moved at any time, suitable for various locations |

| Application | Long-term mining, quarries, and aggregate production | Temporary projects, construction waste recycling, field operations |

If you need long-term, stable operations with high output, a fixed production line is recommended.

If your project requires short-term work with frequent location changes, a mobile crushing production line is more suitable.

Are you looking for a solution for a specific project? If so, we can provide a more detailed analysis based on your needs.